Ballast-free ships

In the realm of ships, ballast is a fixed or transitory weight that must be placed on board to solve or alleviate what I name " ballast-related problems" (BRPs), what means those problems that can fixed by using ballast. For example, BRPs are a poor ship's stability, insufficient or inadequate drafts, propeller(s) incomplete immersion, excessive ship movements at sea, etc.

Fixed ballast is usually made up of concrete mixed with iron nuggets, ingots, cast iron blocks, stones etc., all of which are best placed in the lowest part of the ship, occupying spaces with little or no use for normal service. Therefore fixed ballast is part of the ship's structure or incorporated into it and so travels within the ship along its whole life. Fixed ballast is only used in recreational vessels and small fishing or cargo ships.

Transitory ballast always consists of sea water(or river, lake, etc.) brought into some of the vessel tanks, which normally are a part of her hull structure, before beginning a trip where there is a need to solve any of the BRPs, and that it is pumped out when arriving at the port of destination, where payload is shipped into, intending to solve the existing BRPs without recurring to ballast. It is also possible to undertake a trip by combining liquid ballast and payload.

Physical problems in the ship

Ballast is useful when it solves the presented problem but it also has drawbacks, which I name ballast problems (BPs). Traditionally, the BPs were its cost of acquisition and arrangement in the vessel (in the case of solid ballast), the cost of fuel (motorized vessel) that is consumed for its transport, maintenance costs of the tanks filled with sea water, piping and pumps for its transfer etc.

Biological problems in enviroment

In relatively recent times another problem with liquid ballast has arisen, which is that when the ballasted ship arrives at the loading port to take the cargo, she must empty the ballasted tanks and together with the water also are discharged aquatic animal and vegetable species (Bacteria, microbes, small invertebrates, mollusks, eggs, larvae, plants ...) that were trapped in the water ballast at the home port, and they can be invasive in the local wildlife and cause a very important biological damage in the port of arrival area.

Solutions

A proper ship design will seek to minimize the amount of ballast needed to solve BRP problems by optimizing ship's main dimensions and hull shape and with a cargo and ballast spaces clever arrangement. But usually it is impossible to completely avoid the use of ballast, which is sometimes needed in large quantities and therefore with a strong economic impact on ship's business.

The increasing severity of the of biological pollution problem caused by the discharge of ballast water has led to the international community, within IMO, to agree certain procedures to be incorporated in the ships and ports, as specified in the "International Convention for the Control and Management of ships' Ballast Water and Sediments (BWM Convention)" and will be required from 2012.

This Convention classifies vessels according to their year of construction and the volume of ballast tanks and requires a registration and administration of the ballasting / de-ballasting operations. On some ships, especially those built after 2012, it also requires a chemical treatment of ballast water to kill living species that could contaminate the waters in the arrival port. It is also specified that in ports and terminals where cleaning or repair works in ballast tanks can be performed, they shall be provided with adequate sediments reception facilities.

Solutions recently have been published to eliminate the ballast water in ships and to otherwise solve the BRPs problems. The solutions that I know are the following.

1) Ship hull special forms

This solution is the latest I got known and has been applied in the tanker type design called "Triality", (Ref.3), developed by the Classification Society Det Norske Veritas (DNV) and on which I published a post in this blog here (Ref. 1). It presents great attractions and, according to DNV, allows the total elimination of ballast on big ships and dramatic but not complete decrease in smaller vessels. But it has not yet been implemented in actual ships.

I summarize here below main features of this solution:

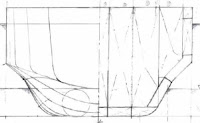

* designing very fine lines in the lower hull form, by the adoption of strongly V shaped transverse sections.

* subdividing the space for cargo tanks more than usual to control the heel, drafts and stresses on the structure of the vessel in port during loading and unloading.

2) Continuous flow of ballast water through spaces prepared to this effect

This solution (Ref.2) has been developed by University of Michigan (UMI) and consists of arranging tanks and piping so that during the ballast trip, water is flowing along double buttom tanks, entering through a hole at the forward ship end and exiting through other(s) aft hole(s) (see photos in a model).

This way at any time ballast water inside the ship is of the type existing in the sea area where the vessel navigates and thus there is not an organisms transfer from one geographic area to a different one.

Obviously this solution does not eliminate the other problems of ballast water, although its inventors say that the ship is not taking ballast but what she does is to remove the buoyancy of a hull part. This observation is really semantic, because sea water is in contact with the ship's structure with its inherent problems. Traditional ballast tanks are replaced by structural pipes that extend below the cargo area and when the ballast trip ends they can be closed and isolated from the sea by valves and then enclosed ballast water can be pumped to the outside through conventional pumps. The actual saving is the ballast water treatment system by chemicals, which is often required in conventionally ballasted ships.

This solution has another drawback and higher costs, because it requires a higher double bottom to get enough ballast capacity below the draft in ship's ballast condition. This requires an increase of the vessel depth to compensate for the loss of cargo volume.

Summary

In my opinion the DNV solution is more drastic because it achieves the total elimination of ballast, at least in large vessels, but only partially in smaller. On the other hand the UMI solution seems to be universal, but it gets only a partial elimination of the ballast problems. In short, the designer should weigh the advantages and disadvantages and check the of production and running costs of both solutions.

References

1 - http://getxoship.blogspot.com/2011/01/triality-innovative-project-of-vlcc.html#more

2 - http://www.glmri.org/downloads/parsons08.pdf

Further Development and Optimization of the Ballast-Free Ship Design Concept

3- Triality VLCC. DNV Tanker Update No.2 2010

1 comment:

Nice blog thannks for posting

Post a Comment